Discover our campus

One campus, one community, one purpose.

Many promising innovations do not make it to completion. This can and must be improved to accelerate the energy transition. This is why the Energy Transition Campus Amsterdam (ETCA) was created by Shell.

Everything in ETCA is about further developing technologies and innovative energy solutions and bringing them to market as quickly as possible. ETCA offers great opportunities and state of the art infrastructure to test and scale game changing ideas.

We offer a location in the heart of Amsterdam with a combination of bright minds, innovative companies, and best of its kind laboratories.

Together, we can really make a difference to provide the world with affordable and increasingly renewable energy.

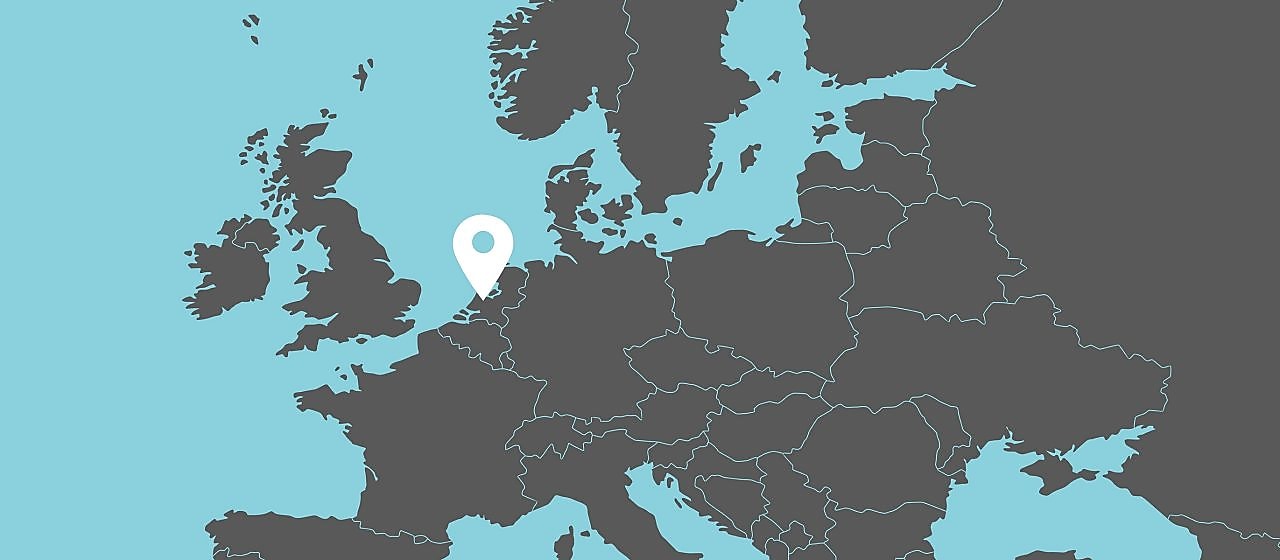

Location, location, location

Energy Transition Campus Amsterdam is in a prime position in Amsterdam just a short ferry ride across from Central Station and just 20km from Amsterdam Schiphol Airport – making the campus well-connected to any destination in the world.

The Energy Transition Campus Amsterdam exists of co-working floors, business suites, office space, laboratories, workshops and test halls.

Here, over 20 innovative companies, our so-called ETCA members, continue to learn, develop, and innovate with one purpose: to solve the world’s biggest energy challenges through collaboration, technology, and innovation.

How do these bright minds find each other and how do they work together efficiently? It all starts with being together under one roof, making it easier to meet the right people that spark new ideas or help to accelerate existing ones.

WHAT WE OFFER

A membership with ETCA

An ETCA membership provides access to the campus and its ecosystem, our (co-working) office floors and ETCA’s events . Members have access to the coffee areas, the common spaces, the meeting and conference rooms and the restaurant, which all can be used to collaborate on challenges in the energy transition. Additional services, such as a gym membership or access to the parking facilities, can be added to the membership. Members are part of ETCA’s active (external and internal) communication and news.

Co-working office floors

The co-working office floors offer an open concept design, where collaborative flex working is stimulated in a shared office environment. In these wings the interactions between organizations are common. These wings also include meeting rooms for group meetings and calls.

Business Suites

Private business suites can be added to your membership and are available for 4-20 persons.

Office space

ETCA also offers independent office units varying in size between 430 – 930 m2 (~28 – 78 workstations) that can be tailor made to suit your company needs.

Laboratories

Our laboratories are designed to scale sustainable technologies and ETCA offers both shared and dedicated lab spaces for rent. ETCA is a large up-and running laboratory facility, so in many cases you can directly benefit from the already-available shared infrastructure (e.g. industrial gasses, waste treatment, environmental permit). ETCA’s facilities can best support the Technology Readiness Levels (TRL) 3 – 6. Exceptions exist (both in the lower and higher TRL end).

Interested in joining our ecosystem? Get in touch! We’re happy to start the conversation.

ETCA – Ben Feringa

Read the transcript

Read the transcript

Title: ETCA – Ben Feringa

Time: 56 seconds

Description

Working together on solutions for the energy transition in the new Energy Transition Campus Amsterdam.

Shell in Amsterdam opens her doors for start-ups, scale-ups, research institutes, academia and mature companies to work together on energy transition solutions. Nobel Prize Winner Ben Feringa reflects on the importance of the new open campus in Amsterdam.

[video]

Video of the outside of the STCA building

[video]

Ben Feringa walks in the frame and smiles in the camera.

[Ben Feringa says]

The idea of the Energy Transition Campus, here in Amsterdam, I think can make an important difference for our future.

[video]

Scientists are walking down the hall at the STCA building.

[Ben says]

Because it means open innovation, bringing together experts, from academia, from society, from industry, like Shell, to work on some of the most challenging issues that we are facing.

[video]

Video outside the STCA building.

[Ben says]

We have complimentary expertises to the whole chain, from fundamental discoveries to the processes and the products of the future.

[video]

Video of the solar panels on top of the STCA building.

[Ben says]

Bringing together the different expertises we can really make the difference. And accelerate the innovation process to a sustainable future.

[video]

Ben and scientists walking and talking at the STCA lab.

[Ben says]

So open innovation, taking advantage of all the knowledge and experience that has been developed over the past decades. That will make the big move forward.

A building for today to solve the challenges of tomorrow

The Energy Transition Campus Amsterdam has 364 solar panels which, together with electricity from Dutch offshore wind farms, provides the building with energy.

The temperature is controlled via underground heat and cold storage together with heat pumps. In winter, the heat sources supply hot water to heat the building and once this has cooled, it is stored in the cold sources in the soil which then cool the building in the summer. When the water is heated up again, it is returned to the hot springs for storage.

This combination of sustainable energy systems ensures that the Energy Transition Campus Amsterdam is sustainable but having a facility that reflects the ambitions of those it houses does not stop at a building run on green energy. ETCA has been awarded LEED Gold certification. LEED stands for Leadership in Energy and Environmental Design and is a globally recognised certification system for building sustainability which looks at the building itself and also the processes that take place inside the building.

The Energy Transition Campus Amsterdam in the environment

Biodiversity

The flora and fauna around and on the building contribute to the biodiversity of the area. The roofs of the first floor are covered with seven different types of plants chosen for their rainwater collection ability to alleviate pressure on the sewers during times of heavy rainfall and to attract all kinds of insects.